Table of Content

1.1 Plant Availability during the Reporting Month

1.2 Defect Rectification for Lamma Extension’s Associated Transmission System

1.3 Summary of EM&A Requirements

2.2 Summary of Results and Observations

3.2 Summary of Results and Observations

4.2 Summary of Results and Observations

4.3 Implementation Status on Thermal Plume and Residual Chlorine Surveys

5.1 Review of Environmental Monitoring Procedures

5.2 Assessment of Environmental Monitoring Results

5.3 Implementation Status of Environmental Mitigation Measures

5.4 Implementation Status of Event/Action Plans

5.5 Implementation Status of Environmental Complaint Handling Procedures

6.1 Outage Plan for the coming 3 months

6.2 Defect Rectification for Lamma Extension’s Associated Transmission System

6.3 Key issues for the coming month

List of Tables

Table 2.1 Air Quality Monitoring Parameter and Frequency

Table 3.1 Noise Monitoring Parameter and Frequency

Table 4.1 Water Quality Monitoring Parameters and Frequencies

Table 5.1 Summary of Action/Limit Level Exceedances on Monitoring Parameters

Table 5.2 Environmental Complaints / Enquiries Received in July 2007

Table 5.3 Outstanding Environmental Complaints / Enquiries Carried Over

List of figure

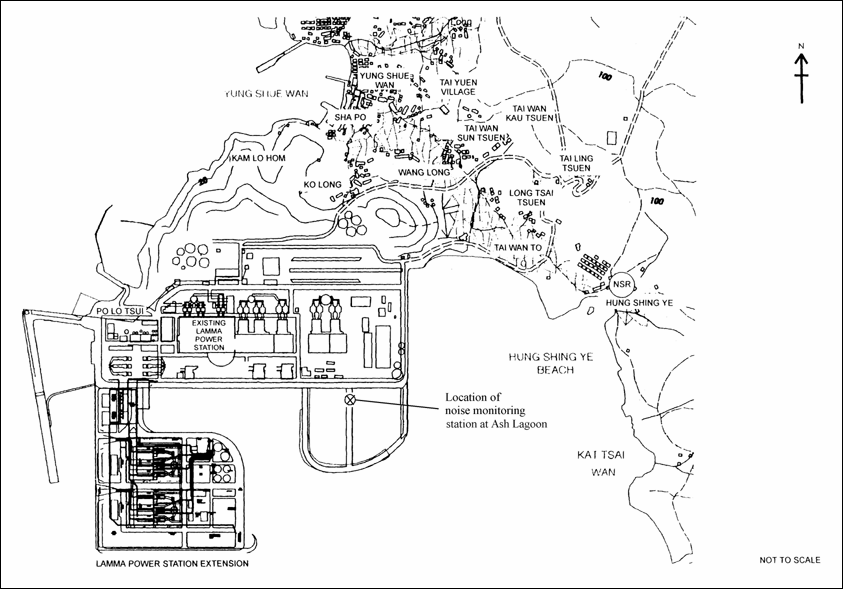

Figure 3.1 Location of Noise Monitoring Station

AppendiX

Appendix B Action and Limit Levels for Air Quality, Noise and Water Quality Monitoring

Appendix C Air Quality Monitoring Results

Appendix D Noise Monitoring Results

Appendix E Summary Results and Observations on Water Quality Monitoring

This is the tenth monthly Environmental Monitoring and Audit (EM&A) report for the Project “Operation of Lamma Power Station Extension” prepared by the Environmental Team (ET). This report presents the results of impact monitoring on air quality, noise, water quality and environmental audit for the operation of the said project in July 2007.

Air quality, noise and water quality monitoring were performed. The results were checked against the established Action/Limit (AL) levels. The implementation status of the environmental mitigation measures, Event/Action Plan and environmental complaint handling procedures were also checked.

Plant Availability

Unit L9 was out of service during the following period:

|

Period |

Remark |

|

21/07/07 21:02 to 22/07/07 02:34 |

Defect Rectification |

Defect Rectification for Lamma Extension’s Associated Transmission System

A defect was recently discovered in one of the newly laid submarine cables from Pak Kok Tsui Landing Point (N5) to Cyberport Landing Point (I1). It had been identified that the defective point of the cable was located at the offshore subsea area near Pak Kok Tsui Landing Point (N5). Preparation work for further fault investigation was in progress.

Environmental Monitoring Works

Environmental monitoring works, as mentioned in the EM&A Manual (Operational phase), were performed during the operation of Lamma Power Station Extension in the reporting period.

Air Quality

No exceedance of Action and Limit levels for stack NOx was recorded in the reporting month

Noise

No exceedance of Action and Limit levels for noise was recorded in the reporting month.

Water Quality

No exceedance of Action and Limit levels for water quality was recorded in the reporting month.

Implementation Status of Environmental Mitigation Measures

Environmental mitigation measures were implemented in the reporting month.

Environmental Complaints

No complaint against the Project was received in the reporting month.

Future Key Issues

Key issues to be considered in the coming month include:

Air Impact

ˇ To continuously monitor the stack NOx for Lamma Power Station Extension.

Noise Impact

ˇ To continuously monitor the noise for Lamma Power Station Extension.

Water Impact

ˇ To continuously carry out the water quality monitoring for Lamma Power Station Extension.

Concluding Remarks

The environmental performance of the project was generally satisfactory.

1. INTRODUCTION

The operational phase Lamma Power Station Extension commenced in mid October 2006 following the completion of erection works and commissioning tests for Unit L9. The Environmental Team (hereinafter called the “ET”) was formed within The Hongkong Electric Co. Ltd (HEC) to undertake Environmental Monitoring and Audit for “Operation of Lamma Power Station Extension” (hereinafter called the “Project”). Under the requirements of Section 6 of Environmental Permit EP-071/2000/C, an EM&A programme for impact environmental monitoring set out in the EM&A Manual (Operational Phase) is required to be implemented. In accordance with the EM&A Manual, environmental monitoring of air quality, noise and water quality are required for the Project.

This report summarizes the environmental monitoring and audit work for the Project for the month of July 2007.

1.1 Plant Availability during the Reporting Month

Unit L9 was out of service during the following period:

|

Period |

Remark |

|

21/07/07 21:02 to 22/07/07 02:34 |

Defect Rectification |

1.2 Defect Rectification for Lamma Extension’s Associated Transmission System

A defect was recently discovered in one of the newly laid submarine cables from Pak Kok Tsui Landing Point (N5) to Cyberport Landing Point (I1). It had been identified that the defective point of the cable was located at the offshore subsea area near Pak Kok Tsui Landing Point (N5). Preparation work for further fault investigation was in progress.

1.3 Summary of EM&A Requirements

The EM&A program requires environmental monitoring for air quality, noise and water quality. The EM&A monitoring work for air quality, noise and water quality are described in Sections 2, 3 and 4 respectively.

The following environmental audits are summarized in Section 5 of the report:

ˇ Environmental monitoring results;

ˇ The implementation status of environmental protection and pollution control / mitigation measures.

The future key issues for the Project will be reported in Section 6 of this report.

In accordance with the EM&A Manual (Operational Phase) for Lamma Extension, stack NOx is continuously monitored. Stack NOx monitoring data would be checked against the Action/Limit Levels stated in the EM&A Manual. The monitoring frequency is shown in Table 2.1 below:

Table 2.1 Air Quality Monitoring Parameter and Frequency

|

Parameter |

Frequency |

|

Hourly Average Stack NOx |

Continuous |

2.2 Summary of Results and Observations

Monitoring of stack NOx was conducted during the operation of Unit L9 in the reporting month. A monthly summary of monitoring data is shown in Appendix C.

No Action/Limit Level exceedance on stack NOx was recorded in the reporting month.

In accordance with the EM&A Manual for Lamma Extension (Operational Phase), continuous noise monitoring at Ash Lagoon is carried out to calculate the noise arising from the operation of Lamma Extension at the critical NSR at Hung Shing Ye. Baseline noise levels are applied for correction to the noise monitoring data. The data after corrections would be checked against the Limit Levels specified in the EM&A Manual.

The noise monitoring location is shown in Figure 3.1. The monitoring parameter and frequency are shown in Table 3.1 below:

Table 3.1 Noise Monitoring Parameter and Frequency

|

Parameter |

Frequency |

Time Period |

|

30-min LAeq |

continuous |

0700-2300 hrs and 2300-0700 hrs of next day |

3.2 Summary of Results and Observations

Continuous noise monitoring was conducted at the monitoring station at Ash Lagoon. The monitoring results are shown in Appendix D.

No Action/Limit Level exceedance on noise was recorded in the reporting month.

Figure 3.1 Location of Noise Monitoring Station

4. WATER QUALITY

In accordance with the EM&A Manual for Lamma Extension (Operational Phase), the monitoring requirements for the EM&A work should strictly follow the discharge licence for L1-L9 & GT57 issued under the Water Pollution Control Ordinance (WPCO).

The parameters as stated in Table 4.1 were monitored and checked against the Action/Limit Levels as given in Appendix B.

Table 4.1 Water Quality Monitoring Parameters and Frequencies

|

Item |

Parameters |

Frequencies |

|

1 |

Cooling Water Temperature Rise |

Daily |

|

2 |

Total Residual Chlorine |

Bi-weekly |

|

3 |

Temperature of Blowdown Effluent |

At least twice per year |

|

4 |

Suspended Solids from Blowdown Effluent |

At least twice per year |

|

5 |

Grease & Oil from Blowdown Effluent |

At least twice per year |

|

6 |

Scum of foam in ambient water |

Daily |

4.2 Summary of Results and Observations

Monitoring of various parameters as listed in Table 4.1 above were carried out during the operation of Unit L9 in the reporting month. A monthly summary of the data is shown in Appendix E.

The data recorded for the monitoring parameters were all below their corresponding Action/Limit Levels. No Action/Limit level exceedance was recorded in the reporting month. There was no foam present within 500 meters of Hung Sing Ye Beach in the reporting month. Details of the foam observation report are also given in Appendix E. The effluent quality was generally satisfactory.

4.3 Implementation Status on Thermal Plume and Residual Chlorine Surveys

One survey for thermal plume and residual chlorine concentration at the seawater around the discharges from the Lamma Power Station and Lamma Power Station Extension shall be carried out after the commissioning of each of the generating units for the Project. The first survey would be conducted in the summer of 2007 tentatively for the first gas-fired combined cycle Unit L9 after EPD’s agreement on the proposed technical requirements for the survey.

No survey was carried out in the reporting month.

5. ENVIRONMENTAL AUDIT

5.1 Review of Environmental Monitoring Procedures

The environmental monitoring procedures were regularly reviewed by the Environmental Team. No modification to the existing monitoring procedures was recommended.

5.2 Assessment of Environmental Monitoring Results

Monitoring results for Air Quality, Noise and Water Quality

The environmental monitoring results for air quality, noise and water quality in July 2007 presented in Sections 2, 3 and 4 respectively are summarized in Table 5.1.

Table 5.1 Summary of Action/Limit Level Exceedances on Monitoring Parameters

|

Item |

Parameter Monitored |

Monitoring Period |

No. of Exceedances In |

Event/Action Plan Implementation Status and Results |

|

|

Action Level |

Limit Level |

||||

|

Air |

|||||

|

1 |

Stack NOx |

01/07/07-31/07/07 |

0 |

0 |

|

|

Noise |

|||||

|

1 |

Noise levels at the critical NSR at Hung Shing Ye calculated by the noise alarm monitoring system |

01/07/07-31/07/07 |

0 |

0 |

|

|

Water |

|||||

|

1 |

Cooling Water Temperature Rise |

01/07/07-31/07/07 |

0 |

0 |

|

|

2 |

Total Residual Chlorine |

01/07/07-31/07/07 |

0 |

0 |

|

|

3 |

Temperature of Blowdown Effluent |

01/07/07-31/07/07 |

N.A. |

N.A.* |

|

|

4 |

Suspended Solids from Blowdown Effluent |

01/07/07-31/07/07 |

N.A. |

N.A.* |

|

|

5 |

Grease & Oil from Blowdown Effluent |

01/07/07-31/07/07 |

N.A. |

N.A.* |

|

|

6 |

Inspection of Scum/Foam in ambient water |

01/07/07-31/07/07 |

0 |

0 |

|

Note: * Monitoring was not scheduled in the reporting month

Land Contamination

There was no land contamination incident happened in the reporting month.

Waste Management

Waste management practice was properly implemented for operation of the project as outlined in the Waste Management Plan for Lamma Power Station Extension. There was no unacceptable environmental impact on waste management in the reporting month.

5.3 Implementation Status of Environmental Mitigation Measures

Mitigation measures detailed in the permits and the EM&A Manual (Operational Phase) are required to be implemented. An updated summary of the Environmental Mitigation Implementation Schedule (EMIS) is presented in Appendix F.

5.4 Implementation Status of Event/Action Plans

The Event/Action Plans for air quality, noise and water quality extracted from the EM&A Manual (Operational Phase) are presented in Appendix A.

5.5 Implementation Status of Environmental Complaint Handling Procedures

In July 2007, no complaint against the Project was received.

Table 5.2 Environmental Complaints / Enquiries Received in July 2007

|

Case Reference / Date, Time Received / Date, Time Concerned |

Descriptions / Actions Taken |

Conclusion / Status |

|

Nil |

N/A |

N/A |

Table 5.3 Outstanding Environmental Complaints / Enquiries Carried Over

|

Case Reference / Date, Time Received / Date, Time Concerned |

Descriptions / Actions Taken |

Conclusion / Status |

|

Nil |

N/A |

N/A |

6.1 Outage Plan for the coming 3 months

The major outage plan for the next 3 months is shown below:

|

Date |

Remark |

|

18/10/2007 to 21/10/2007 |

GT57 Pressure Reduction System Installation |

6.2 Defect Rectification for Lamma Extension’s Associated Transmission System

The cable tail laid at seabed near Pak Kok Tsui Landing Point (N5) would be taken out and recoiled onto a working barge for fault investigation.

Since the fault investigation would be carried out on a cable installation barge and subsequent repair work would be similar to the cable laying work, all requirements stipulated in the Environmental Permit for Lamma Power Station Extension (EP-071/2000/C) would be complied with.

6.3 Key issues for the coming month

Key issues to be considered in the coming month include:

Air Impact

ˇ To continuously monitor the stack NOx for Lamma Power Station Extension.

Noise Impact

ˇ To continuously monitor the noise for Lamma Power Station Extension.

Water Impact

ˇ To continuously carry out the water quality monitoring for Lamma Power Station Extension.

7. CONCLUSION

Environmental monitoring was performed as required in the reporting month. All monitoring results were checked and reviewed.

No Action/Limit level exceedance on stack NOx was recorded in the reporting month

No Action/Limit level exceedance on noise was recorded in the reporting month.

No Action/Limit level exceedance on water quality parameters was recorded in the reporting month.

Environmental mitigation measures recommended in the EM&A Manual for the operational activities were implemented in the reporting month. No complaint against the Project was received in the reporting month. No prosecution was received for this Project in the reporting period.

The environmental performance of the Project was generally satisfactory.

Table A.1 Event/Action Plan for Air Quality

|

Exceedance |

ET Leader |

IEC |

Operations Engineer |

|

Action Level |

|||

|

Exceedance of one sample |

Identify source; Inform IEC verbally; Repeat measurement to confirm finding. |

Check monitoring data submitted by ET Leader and advise ET Leader for any finding. |

Rectify any unacceptable practice; Amend any working methods if appropriate. |

|

|

|

|

|

|

Exceedance of two or more consecutive samples |

Identify source; Inform IEC verbally; Repeat measurement to confirm finding; Increase monitoring frequency; Discuss with Operations Engineers on remedial actions required; If exceedance stops, discontinue additional monitoring. |

Check monitoring data submitted by ET Leader and advise ET Leader for any finding; Verify the implementation of the remedial measures; |

Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions. |

|

Limit level |

|||

|

Exceedance of one sample |

Repeat measurement to confirm finding; Identify the source(s) of the impact. Verbally inform IEC and EPD of the exceedance as soon as practicable; Discuss with Operations Engineers on remedial actions required; Increase monitoring frequency; Assess the effectiveness of the remedial actions and keep IEC and EPD informed of the results. |

Check monitoring data submitted by ET Leader and advise ET Leader of any finding; Verify the implementation of the remedial measures.

|

Take immediate action to avoid further exceedances; Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions.

|

|

|

|

|

|

|

Exceedance of two or more consecutive samples |

Identify source; Identify the source(s) of the impact. Verbally inform IEC and EPD of the exceedance as soon as practicable; Repeat measurement to confirm finding; Increase monitoring frequency; Carry out analysis on existing control procedures to determine possible mitigation to be implemented; Discuss with Operations Engineers on the remedial actions to be taken; If exceedance stops, discontinue additional monitoring. |

Provide feedback and advise ET Leader/Operations Engineers on the effectiveness of the remedial actions proposed by them; Verify the implementation of the remedial measures. |

Take immediate action to avoid further exceedance; Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions; Check the suspected defective parts if the problem still does not come under control. |

Table A.2 Event/Action Plan for Noise

|

Exceedance |

ET Leader |

IEC |

Operations Engineer |

|

Action Level |

If the complaint against Lamma Extension operation is valid, identify the source(s) of the noise and propose remedial measures if necessary; |

Verify the implementation of the remedial measures.

|

Discuss with ET Leader on remedial actions required;

Implement the agreed remedial actions. |

|

Limit Level |

Check monitoring data to confirm findings;

Identify the source(s) of the impact. If the exceedance is found to be valid and due to the Lamma Extension operation, verbally inform IEC and EPD of the exceedance as soon as practicable;

Discuss with Operations Engineers on remedial actions required. |

Check monitoring data submitted by ET Leader and advise ET Leader of any finding;

Verify the implementation of the remedial measures. |

Take action to avoid further exceedance;

Discuss with ET Leader on the remedial actions required;

Implement the agreed remedial actions.

|

Table A.3 Event/Action Plan for Water Quality

|

Exceedance |

ET Leader |

IEC |

Operations Engineer |

|

Action Level |

|

||

|

Exceedance on one sampling day |

Identify source(s) of impact; Verbally inform IEC.

|

Check monitoring data submitted by ET Leader and advise ET Leader for any findings. |

Rectify unacceptable practice; Amend any working methods if appropriate. |

|

Exceedances on more than one consecutive sampling day |

Identify source(s) of impact; Verbally inform IEC; Repeat in-situ measurements to confirm findings; Discuss with Operations Engineers on remedial actions required; Increase monitoring frequency; If exceedance stops, discontinue additional monitoring.

|

Check monitoring data submitted by ET Leader and advise ET Leader for any finding; Verify the implementation of the remedial measures. |

Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions. |

|

Limit Level |

|

|

|

|

Exceedance on one sampling day |

Identify the source(s) of impact; Verbally inform IEC and EPD of the exceedance, as soon as practicable; Repeat measurement to confirm finding; Discuss with Operations Engineers on remedial actions required; Increase monitoring frequency; Assess the effectiveness of the remedial actions and keep IEC and EPD informed of the results.

|

Check monitoring data submitted by ET Leader and advise ET Leader for any finding; Verify the implementation of the remedial measures.

|

Take immediate action to avoid further exceedance; Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions. |

|

Exceedances on more than one consecutive sampling day |

Identify the source(s) of impact; Verbally inform IEC and EPD of the exceedance as soon as practicable; Repeat measurement to confirm finding; Discuss with Operations Engineers on remedial actions required; Increase monitoring frequency; Carry out analysis on existing control procedures to determine possible mitigation to be implemented; If exceedance stops, discontinue additional monitoring.

|

Provide feedback and advise ET Leader/Operations Engineers on the effectiveness of the remedial actions proposed; Verify the implementation of the remedial measures. |

Take immediate action to avoid further exceedance; Discuss with ET Leader on remedial actions required; Implement the agreed remedial actions; Check the suspected defective parts if the problem still does not come under control. |

Appendix B Action and Limit Levels for Air Quality, Noise and Water Quality Monitoring

B.1 Air

|

Parameter |

Frequency |

Action |

Limit |

|

Hourly Average Stack NOx |

Continuous |

81 mg/Nm3 |

90 mg/Nm3 |

B.2. Noise

|

Parameter |

Frequency |

Action |

Limit |

|

Noise Levels at the critical NSR at Hung Shing Ye calculated by the noise alarm monitoring system |

Continuous |

When more than one complaint is received within two weeks, which are concerning the same event or location |

a. 60 dB(A) in LAeq,30 min (07:00-23:00 hrs) b. 50 dB(A) in LAeq,30 min (23:00-07:00 hrs on next day) |

B.3 Water

|

Monitoring Area / Location |

Parameters to be Monitored |

Frequency |

Concentration Not to Be Exceeded |

Action |

Limit |

|

Trade Effluent Cooling Water |

Temperature |

Daily, when the combined cycle unit is operating |

Temperature at outfall should not exceed that at intake by > 10°C |

9.5°C |

+10°C above intake |

|

Total Residual Chlorine |

Bi-weekly, when the combined cycle unit is operating |

0.5mg/L |

0.47 |

0.5 |

|

|

Trade Effluent Boiler Blowdown |

Temperature |

At least twice per year, when the combined cycle unit is operating |

40°C |

- |

40°C |

|

Suspended Solids |

At least twice per year, when the combined cycle unit is operating |

30 mg/L |

- |

30 |

|

|

Grease & Oil |

At least twice per year, when the combined cycle unit is operating |

20 mg/L |

- |

20 |

|

|

Marine waters cooling water outfall |

Scum of foam in ambient water |

Daily, when the combined cycle unit is operating |

No scum within 500 m of Hung Shing Ye Beach |

When scum passes the station south-west corner and north-west corner |

No scum within 500 m of Hung Shing Ye Beach |

Appendix C Air Quality Monitoring Results

Site: Lamma Power Station – Unit L9

Month: July 2007

Monthly Summary of Stack NOx

|

Date |

Daily Maximum Stack NOx concentration (mg/Nm3)# |

|

1/7/2007 |

47 |

|

2/7/2007 |

48 |

|

3/7/2007 |

47 |

|

4/7/2007 |

47 |

|

5/7/2007 |

46 |

|

6/7/2007 |

45 |

|

7/7/2007 |

46 |

|

8/7/2007 |

47 |

|

9/7/2007 |

46 |

|

10/7/2007 |

45 |

|

11/7/2007 |

46 |

|

12/7/2007 |

45 |

|

13/7/2007 |

44 |

|

14/7/2007 |

46 |

|

15/7/2007 |

46 |

|

16/7/2007 |

46 |

|

17/7/2007 |

45 |

|

18/7/2007 |

44 |

|

19/7/2007 |

44 |

|

20/7/2007 |

44 |

|

21/7/2007 |

45 |

|

22/7/2007 |

47 |

|

23/7/2007 |

44 |

|

24/7/2007 |

44 |

|

25/7/2007 |

45 |

|

26/7/2007 |

44 |

|

27/7/2007 |

46 |

|

28/7/2007 |

46 |

|

29/7/2007 |

46 |

|

30/7/2007 |

44 |

|

31/7/2007 |

44 |

Note: # - Hourly average value. Expressed as at 0ēC, 101.325kPa, dry and corrected to 15% O2 condition.

Appendix D Noise Monitoring Results

Site: Lamma Power Station Extension

Measurement Location: Ash Lagoon

Measurement Parameter: 30-min Leq (07:00-23:00 hrs and 23:00-07:00 hrs on next day)

|

Date |

Time |

Calculated Noise Level at NSR at Hung Shing Ye (dB(A)) |

Limit Noise Level (dB(A)) |

|

|

Max |

Avg |

|||

|

07:00-23:00 |

--- |

--- |

60 |

|

|

01/07/2007 |

23:00-07:00 |

27 |

25 |

50 |

|

02/07/2007 |

07:00-23:00 |

34 |

31 |

60 |

|

02/07/2007 |

23:00-07:00 |

39 |

34 |

50 |

|

03/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

03/07/2007 |

23:00-07:00 |

28 |

27 |

50 |

|

04/07/2007 |

07:00-23:00 |

37 |

35 |

60 |

|

04/07/2007 |

23:00-07:00 |

8 |

8 |

50 |

|

05/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

05/07/2007 |

23:00-07:00 |

26 |

23 |

50 |

|

06/07/2007 |

07:00-23:00 |

35 |

33 |

60 |

|

06/07/2007 |

23:00-07:00 |

27 |

25 |

50 |

|

07/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

07/07/2007 |

23:00-07:00 |

--- |

--- |

50 |

|

08/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

08/07/2007 |

23:00-07:00 |

39 |

37 |

50 |

|

09/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

09/07/2007 |

23:00-07:00 |

35 |

35 |

50 |

|

10/07/2007 |

07:00-23:00 |

28 |

25 |

60 |

|

10/07/2007 |

23:00-07:00 |

--- |

--- |

50 |

|

11/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

11/07/2007 |

23:00-07:00 |

27 |

24 |

50 |

|

12/07/2007 |

07:00-23:00 |

35 |

33 |

60 |

|

12/07/2007 |

23:00-07:00 |

31 |

26 |

50 |

|

13/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

13/07/2007 |

23:00-07:00 |

--- |

--- |

50 |

|

14/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

14/07/2007 |

23:00-07:00 |

25 |

23 |

50 |

|

15/07/2007 |

07:00-23:00 |

31 |

31 |

60 |

|

15/07/2007 |

23:00-07:00 |

27 |

25 |

50 |

|

16/07/2007 |

07:00-23:00 |

35 |

32 |

60 |

|

16/07/2007 |

23:00-07:00 |

--- |

--- |

50 |

|

17/07/2007 |

07:00-23:00 |

42 |

40 |

60 |

|

17/07/2007 |

23:00-07:00 |

22 |

22 |

50 |

|

18/07/2007 |

07:00-23:00 |

41 |

37 |

60 |

|

18/07/2007 |

23:00-07:00 |

28 |

27 |

50 |

|

19/07/2007 |

07:00-23:00 |

36 |

33 |

60 |

|

19/07/2007 |

23:00-07:00 |

33 |

26 |

50 |

|

20/07/2007 |

07:00-23:00 |

42 |

38 |

60 |

|

20/07/2007 |

23:00-07:00 |

28 |

24 |

50 |

|

21/07/2007 |

07:00-23:00 |

40 |

37 |

60 |

|

21/07/2007 |

23:00-07:00 |

35 |

30 |

50 |

|

22/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

22/07/2007 |

23:00-07:00 |

32 |

27 |

50 |

|

23/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

23/07/2007 |

23:00-07:00 |

28 |

23 |

50 |

|

24/07/2007 |

07:00-23:00 |

39 |

34 |

60 |

|

24/07/2007 |

23:00-07:00 |

33 |

29 |

50 |

|

25/07/2007 |

07:00-23:00 |

39 |

34 |

60 |

|

25/07/2007 |

23:00-07:00 |

35 |

31 |

50 |

|

26/07/2007 |

07:00-23:00 |

44 |

40 |

60 |

|

26/07/2007 |

23:00-07:00 |

33 |

29 |

50 |

|

27/07/2007 |

07:00-23:00 |

45 |

41 |

60 |

|

27/07/2007 |

23:00-07:00 |

33 |

29 |

50 |

|

28/07/2007 |

07:00-23:00 |

35 |

31 |

60 |

|

28/07/2007 |

23:00-07:00 |

31 |

29 |

50 |

|

29/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

29/07/2007 |

23:00-07:00 |

34 |

30 |

50 |

|

30/07/2007 |

07:00-23:00 |

38 |

36 |

60 |

|

30/07/2007 |

23:00-07:00 |

34 |

29 |

50 |

|

31/07/2007 |

07:00-23:00 |

--- |

--- |

60 |

|

31/07/2007 |

23:00-07:00 |

32 |

27 |

50 |

Note: “--- “ represents the measured noise monitoring data lower than the established notional background level/discarded under strong wind.

Appendix E Summary Results and Observations on Water Quality Monitoring

Maximum Outlet Temperature Rise (Deg. Celsius) of Cooling Water at C.W. Outfall No.3 Serving L9 Condensers

Weighted by Flowrates of Individual Streams (July 2007)

|

Date |

Maximum Outlet Temperature Rise (Deg. Celsius) |

|

01/07/2007 |

8.2 |

|

02/07/2007 |

8.6 |

|

03/07/2007 |

8.4 |

|

04/07/2007 |

8.3 |

|

05/07/2007 |

8.3 |

|

06/07/2007 |

8.4 |

|

07/07/2007 |

8.4 |

|

08/07/2007 |

8.2 |

|

09/07/2007 |

8.6 |

|

10/07/2007 |

8.6 |

|

11/07/2007 |

8.4 |

|

12/07/2007 |

8.4 |

|

13/07/2007 |

8.4 |

|

14/07/2007 |

8.4 |

|

15/07/2007 |

8.2 |

|

16/07/2007 |

8.6 |

|

17/07/2007 |

8.4 |

|

18/07/2007 |

8.4 |

|

19/07/2007 |

8.4 |

|

20/07/2007 |

8.4 |

|

21/07/2007 |

8.6 |

|

22/07/2007 |

8.5 |

|

23/07/2007 |

8.5 |

|

24/07/2007 |

8.5 |

|

25/07/2007 |

8.4 |

|

26/07/2007 |

8.4 |

|

27/07/2007 |

8.5 |

|

28/07/2007 |

8.9 |

|

29/07/2007 |

8.4 |

|

30/07/2007 |

8.4 |

|

31/07/2007 |

8.4 |

Total Residual Chlorine Level at C.W. Outfall No. 3 (July 2007)

|

Date of sampling |

05/07/2007 |

20/07/2007 |

|

Total Residual Chlorine, mg/L |

0.42 |

0.44 |

Blowdown from Unit L9 Steam Turbine and HRSG to C.W. Outfall No. 3 (July 2007)

|

Source of Discharge |

HSRG |

Steam Turbine |

|

Suspended Solid, mg/L |

# |

# |

|

Grease & Oil, mg/L |

# |

# |

|

Temperature, Deg. Celsius |

# |

# |

Observation of Scum Formation in Marine Waters Mixing Zone at Lamma Power Station Extension (July 2007)

|

Date |

Observation |

|

01/07/2007 |

No scum within

500m of |

|

02/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

03/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

04/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

05/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 & No.2 |

|

06/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

07/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

08/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

09/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 & No.2 |

|

10/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and defoamer added to Outfalls No.1 |

|

11/07/2007 |

No scum within

500m of |

|

12/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

13/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

14/07/2007 |

No scum within

500m of |

|

15/07/2007 |

No scum within

500m of |

|

16/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

17/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

18/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

19/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

20/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

21/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

22/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

23/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

24/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

25/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

26/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

27/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

28/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall, dispersed by ferry and defoamer added to Outfall No.1 |

|

29/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

30/07/2007 |

No scum within 500m of HSY Beach & NW/SW corner of the Station; Some foam outside CW Outfall and dispersed by ferry |

|

31/07/2007 |

No scum within

500m of |

|

Note:

|

|

|

1. # Monitoring was not scheduled in the reporting month. |

|

|

2. The water spraying pump of foam suppression system at C.W. Outfall was in service in the reporting month. |

|

|

EM&A Log Ref. |

Mitigation Measures |

Implementation Status |

|

|

Air Quality |

|

|

A1 |

Implement the gas-fired units as base-load units. For the existing power station, the more efficient units incorporating FGD and low NOx systems shall be operated first under normal situation to meet system demand. In case of any deviations from this, EPD shall be notified of the details and circumstances for the deviation. |

Complied |

|

A2 |

HEC shall undertake annual revisions and update of its GHG emissions inventory, which covers all HEC existing facilities and new extension, for at least the six GHGs specified under the Kyoto Protocol (CO2, CH4, N2O, HFCs, PFCs and SF6). The inventory shall be established and maintained in accordance with the latest IPCC Guidelines or any other guidelines issued by Government, with details documented for regular reviews and updates. The inventory shall be reported on an annual basis, including actual figures and targets for the previous and current years, as well as the next year's forecast. Discrepancies for actual versus target figures and actions for improvement or enhancement shall be discussed. HEC shall update the inventory according to the figures of the electricity load forecast, upon every subsequent review by the Government. This shall also be reported in the annual report.

(The annual report of GHG emissions inventory shall be deposited with the Director of Environmental Protection within three months after the end of the reporting period.) |

Complied |

|

|

|

|

|

|

Water Quality |

|

|

B1 |

No further mitigation measures were found to be necessary provided the discharge of cooling water and residual chlorine are kept below the rates assumed in the water quality assessment*.

*All discharges of effluent/wastewater shall be controlled through licensing under the Technical Memorandum for Effluents Discharged into Drainage and Sewerage Systems. Inland and Coastal Waters, issued under Section 21 of the Water Pollution Control Ordinance. |

Complied |

|

|

|

|

|

|

Noise |

|

|

C1 |

HEC shall implement the gas-fired units for based-load operation to minimize the noise generated from the existing units. |

Complied |

|

|

|

|

|

|

Landscape & Visual impacts |

|

|

D1 |

No mitigation measures were considered necessary. |

N/A |

|

|

|

|

|

EM&A Log Ref. |

Mitigation Measures |

Implementation Status |

|

|

LAND CONTAMINATION AND WASTE MANAGEMENT |

|

|

E1 |

HEC shall maintain records of the following items:

- integrity testing of light oil tanks*;

- quantities of chemical and chemical waste; - incident of spillage and remediation actions; and - emergency response training and drills.

* As the Light Gas Oil (LGO) for Lamma Extension is supplied from the existing LGO storage tanks located at Lamma Power Station, there is no LGO storage tank at Lamma Extension.

|

Complied |

|

|

Marine Ecology |

|

|

F1 |

No mitigation measures were considered necessary. |

N/A |

|

|

|

|

|

|

fisheries |

|

|

G1 |

No mitigation measures were considered necessary. |

N/A |

|

|

|

|

|

|

RISK ASSESSMENT |

|

|

H1 |

No mitigation measures were considered necessary. |

N/A |