CEO’S REPORT

In 2016, HK Electric and CLP jointly began an Environmental

Impact Assessment (EIA) as part of the overall feasibility study

to construct an offshore liquefied natural gas (LNG) terminal

using floating storage and regasification unit technology,

to receive LNG from overseas. The terminal will provide

HK Electric with direct access to and enhance bargaining

power in the international market for gas supplies. The

EIA is scheduled to be completed at the end of 2017 and

subject to timely Government approvals the terminal will be

constructed and commence operations in 2020.

ACHIEVING OPTIMISED GENERATION

PERFORMANCE

Gas-fired generation accounted for over 33% of HK Electric’s

total electricity output in 2016 with coal-fired generation

accounting for the remainder. Natural gas was sourced

mainly from Australia and Qatar while low-sulphur coal came

from Indonesia, Russia and Australia. During the year, plant

availability at LPS stood at 85.6%.

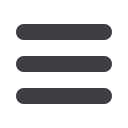

LPS operates eight coal-fired units, two gas-fired combined

cycle units and five oil-fired open cycle gas turbine units. This

is supplemented by Lamma Winds, a commercial-scale wind

turbine and a solar power system consisting of 8,662 thin-

film photovoltaic panels.

Emissions reduction is a strong focus area for the

Government and targets are constantly being tightened.

Our performance continued to achieve or surpass statutory

requirements. In October 2016 the Government published

Technical Memorandum no. 6 (TM6), which set more

stringent emission allowances for the electricity sector from

2021 onwards. As compared with the emission allowances

for 2020 set under the Technical Memorandum no. 5,

TM6 will further tighten emissions of sulphur dioxide (SO

2

),

nitrogen oxides (NO

X

) and respirable suspended particulates

(RSP) by 8%, 2% and 10% respectively for HK Electric. We

An infrared thermal imaging system comprising

15 infrared cameras and 15 normal vision cameras

was installed at the coal bunker floor at Lamma Power

Station for online monitoring of the area. The system

will provide early warning of any incipient fire incidents

and also monitor the coal bunkers and conveyors for any

anomalies. Additionally, a carbon monoxide detection

system was installed at the coal bunkers for early

detection of any smouldering coal inside the bunker.

These early warning alarm signals allow for timely and

appropriate actions to tackle the “hot spots” inside the

coal bunkers, significantly enhancing safety.

THERMAL IMAGING SYSTEM AND

CARBON MONOXIDE DETECTION AT COAL BUNKER

HK Electric’s solar power system helps reduce carbon footprint.

10

HK ELECTRIC INVESTMENTS